Typically to transmit the data after it has been programmed by software to a CNC machine, we need to have a computer and a transfer adapter to connects directly (if connected via parallel port) with CNC machines and dedicated DNC software (as CimcoEdit, DosteskDNC, ProDNC ...) to send data/Gcode file to CNC machine.

|

| Transfer Gcode file from computer to CNC machine |

This caused some defect:

• Cost expenses: We will have to take some cost to equip a computer

• Wasted place: Placing the computer in the production area is also a problem for businesses, we need approximately 2m2 for the placement. Moreover, the accessories such as wires, cables also cost area

• Instability: If computer was infected, when transmitting data to CNC machine will do the wrong data (caused by virus) makes CNC be incorrect, or if one of the computer’s peripherals damaged also lead to instability

|

|

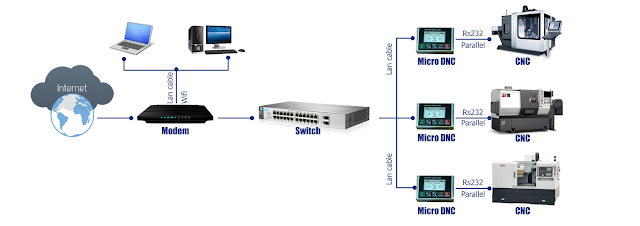

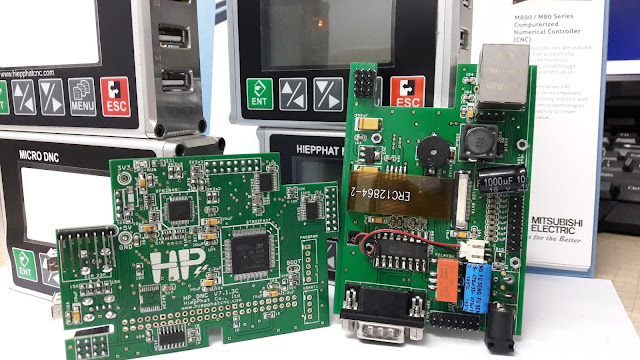

DNC Tranfer Device basic model

|

DNC Transfer Device

is to transmit data to the CNC after being programmed. The inputs of this device is the USB port, Ethernet port or SD Card, we will copy the data after programmed into USB, memory card, (or transmit directly via Ethernet port) and plug in device DNC. The output of this decive is a RS232 port or parallel port, It need to supply power to devices through a adapter or take power directly from the CNC machine via RS232 cable or parallel cable

Advantages

• Cost cheap: Using MICRO DNC will save a significant cost

• Do not waste space: Due to compact so will not waste space in the production area.

• Stable, Simple operation and does not take much time, can work continuously for long time

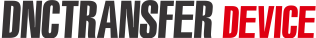

DNC Transfer Device - MICRO DNC

MICRO DNC is a device used to transmit programs/send file/trasfer Gcode file to CNC machine (eg CNC milling machine, CNC Lathe, CNC Router, computerized embroidery machines ...). This transmitter is a compact design, paste directly to the CNC body by the magnet, not occupy factory area, quick and easy ... as alternatives to instead computers to transmit data to CNC machine

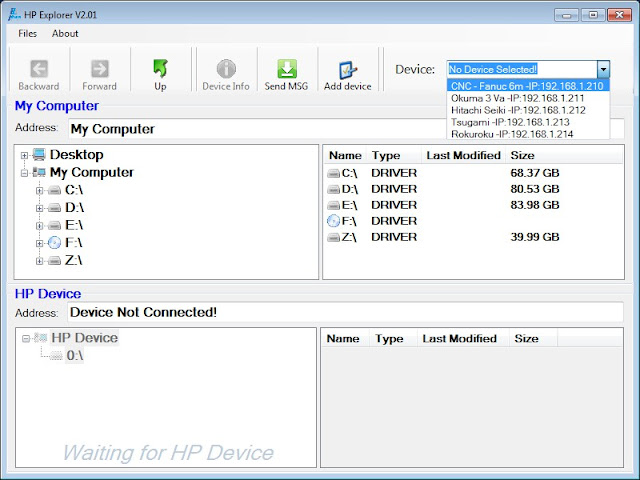

MICRO DNC compatible with CNC machines type such as: all operating systems Fanuc, Mitsubishi, Yasnac, Okuma, Mazak ...

• Reads USB 2.0, SD card CARD of all brands and various capacities.

• Has the memory of 2 to 4 Gb capacity depending on customer needs

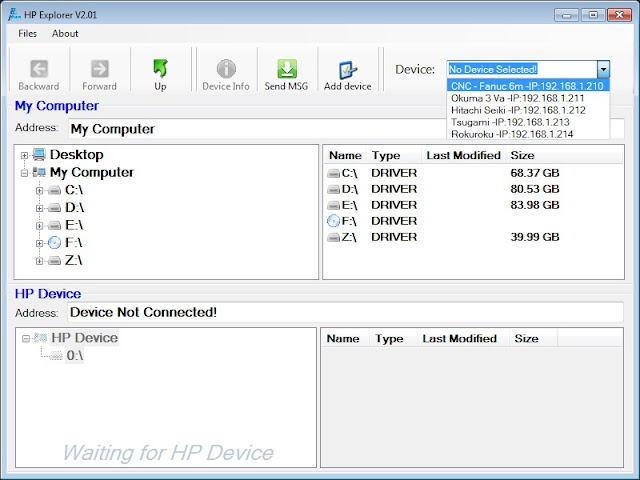

• Can be transmitted over the network via an Ethernet port or WiFi

• Reading is the long file names up to 255 characters

• Graphic LCD very intuitive

• In addition to data transmission to CNC machines, MICRO DNC can take out programs, parameters ... from the CNC machine.

• Automatic return to the first file after the trasmitting completely

• Select the files you want to transfer in a list displayed on the LCD screen

• Set the function and parameters with the button, displayed directly on the LCD Graphic, simple, intuitive

• Speed baudrate up to 19.200bps (1200,2400,4800, 9600, 19200). Change the data transfer rate for parallel ports.

• The warranty period is 2 years, the cost of repairs after the warranty period are low.

SPECIFICATIONS

| Name | DNC Transfer Device - MICRO DNC |

| Orgin | DNC Solutions |

| Image |  |

| Features |

- Size: 140x100x30mm.

- Weight: 300g.

- Aluminum shell

- 03 magnet

- 01 DC power port.

- 01 USB port.

- 01 Sdcard port

- 01 RJ45 ports

- 01 port RS232

- 01 LCD monitor

- 05 buttons to customize

|

| Power |

- 12V DC adapter

- Or use electricity from the RS232 port or parallel port.

|

| Compatible |

- All OS of Fanuc

- Mitsubishi

- Mori Sheiki

- Yasnas

- Mazak

- Okuma...

|

| Hightlight |

- Transfer data via port RS232

- Read data/parameter from CNC machine

- Read file from any USB

- Read file with format *.TXT, *.NC, *.TAP.

- Show % transmitted

|